How WHISCERS works

WHISCERS™ is a three part process:

01

A 3D laser scanner measures the internal dimensions of a room. The digital data is then downloaded to an off-site cutting machine.

02

The machine cuts the insulation boards with great accuracy. Software optimises the cut to minimise wastage.

03

The boards are delivered to site as a kit and are then fitted to the walls with the minimum of noise, mess and disruption.

The Process

The innovative process is the result of a partnership between Laker BMS Ltd and the Sustainable Energy Academy. It was developed as a volume solution for retrofitting older and hard-to-treat social housing stock on a nationwide scale to address the duel challenges of reducing carbon emissions in existing stock and fuel poverty for residents, whilst at the same time making homes warmer and more energy efficient.

There are seven million of these homes in the UK - two million in London alone. Up to 40% of the heat loss in these homes passes through the external walls and in most cases, due to planning restrictions, IWI is the only realistic option.

WHISCERS™ is faster, better and more cost-effective than traditional insulating methods. With low mess, little noise and minimal disruption, as well as being able to insulate a room in 90 minutes with residents remaining at home, WHISCERS™ is an ideal way of retrofitting hard-to-treat properties.

The benefits

WHISCERS™ provides many benefits over traditional IWI methods:

Developed with residents in mind

It is a speedy process that minimises mess and disruption in the home, so residents can get on with their lives with the minimum of inconvenience.

Accuracy of measurement

Laser scanning provides far greater accuracy of measurement.

Speed of measurement

The dimensions of a typical wall can be collated in 10 minutes, as opposed to 30 minutes by traditional methods, so a typical three bedroom house can be surveyed in 60 to 90 minutes.

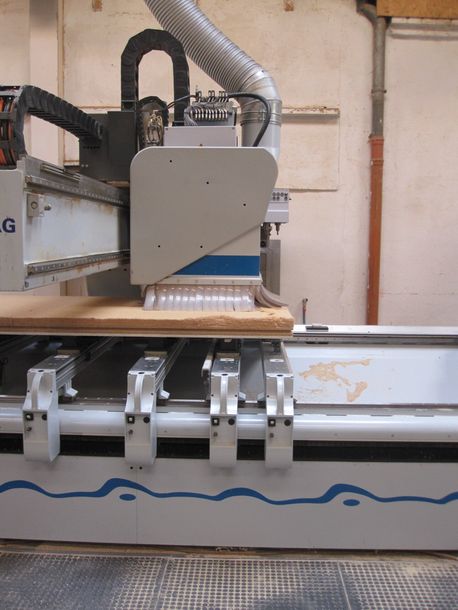

Automated, off-site cutting using a CNC cutting machine

Little mess in the home, greater accuracy and lower material costs than hand-cutting. Less material waste.

Faster Installation

Boards arrive on site and can generally be fitted in 90 minutes per room or less, with lower labour costs.

Residents can remain at home

Less disruption, no relocation costs, minimum noise, mess and faster process.